Applications for Ohio Farm Bureau Health Plans now available

Members have three ways to apply: contacting a certified agent, calling 833-468-4280 or visiting ohiofarmbureauhealthplans.org.

Read MoreThe next time you hear the phrase “processed food” used as a criticism of our modern food culture, think about Bob Bowers, Jr. and his third generation cider mill in Hocking County.

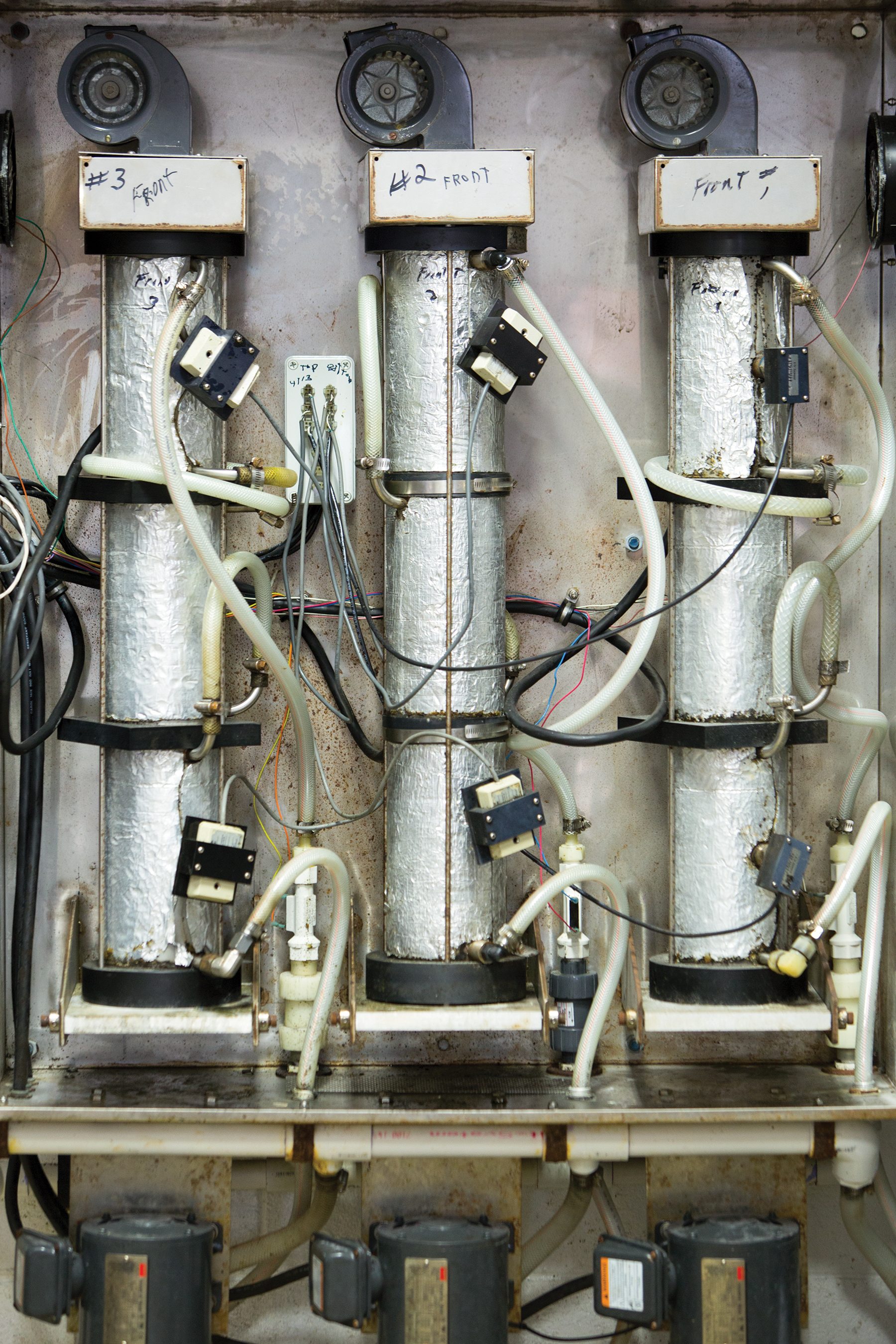

For Bowers, ultraviolet light processing of apple cider was the “silver bullet” that preserved his business. Several years ago, he was mulling over whether to heat pasteurize his apple cider to reduce pathogens like E. coli or sell it as unpasteurized. Neither option was very appealing to him. He felt heat pasteurization slightly flattened the taste of his cider. And continuing to make it the way his family had been doing since the 1930s on their Hocking County farm would mean labeling it as unpasteurized, which could “kill or hurt your business,” he said.

Then Bowers heard the U.S. Food and Drug Administration was looking into approving UV processing to kill harmful bacteria in fruit and vegetable juices. He became one of the first cider processors in Ohio to use this technology in which cider is pumped into a clear tube and briefly exposed to UV light, killing any pathogens.

Over the past 17 years, Bowers, a Hocking County Farm Bureau member, has tinkered with the process and today runs 960 gallons an hour through three UV tubes. He praised the low cost to purchase and run the equipment – the equivalent of running three hair dryers at once. UV processing equipment is about one-fourth the price of a heat pasteurization unit, according to Cornell University microbiologist and food safety expert Randy Worobo, who is credited with introducing the idea of using ultraviolet light to reduce harmful bacteria in fresh juices.

“We invested in the equipment to protect our business. Using it has allowed us to keep our blend the same and protect customers,” said Bowers, whose family farm, Laurelville Fruit Farm, processes up to 30,000 gallons of cider every year.

I guess you could say ultraviolet processing helped save the small cider industry,” said Abby Snyder, a Ross County Farm Bureau member who is working with Worobo on her doctorate degree in food microbiology at Cornell. “After a rash of juice-associated (food-borne illness) outbreaks in the ’80s and ’90s, new regulations were introduced that require wholesale juice be treated to eliminate food-borne pathogens. For the smaller cider producers, it was an economic burden to purchase thermal pasteurization equipment, and many didn’t like how it changed the flavor of their product,” she said.

I guess you could say ultraviolet processing helped save the small cider industry,” said Abby Snyder, a Ross County Farm Bureau member who is working with Worobo on her doctorate degree in food microbiology at Cornell. “After a rash of juice-associated (food-borne illness) outbreaks in the ’80s and ’90s, new regulations were introduced that require wholesale juice be treated to eliminate food-borne pathogens. For the smaller cider producers, it was an economic burden to purchase thermal pasteurization equipment, and many didn’t like how it changed the flavor of their product,” she said.

Snyder said this is just one of many innovative processes that have helped preserve or grow parts of the food industry. Here’s a look at some of the industries that have benefited the most from these creative processes.

‘Baby’ carrots

Frustration over food waste led a California farmer to revolutionize the carrot industry in the mid-1980s. Mike Yurosek of Newhall, Calif., was frustrated grocery stores were rejecting his “ugly” carrots, i.e. those that weren’t long and straight. He bought an industrial bean cutter and started cutting up broken or odd-shaped carrots into uniform, smaller sizes and selling them in packages.

Frustration over food waste led a California farmer to revolutionize the carrot industry in the mid-1980s. Mike Yurosek of Newhall, Calif., was frustrated grocery stores were rejecting his “ugly” carrots, i.e. those that weren’t long and straight. He bought an industrial bean cutter and started cutting up broken or odd-shaped carrots into uniform, smaller sizes and selling them in packages.

The smaller carrots, marketed as baby carrots, became wildly popular with youngsters loving their smaller size and cooks embracing the convenience of adding them to recipes. Sales of the vitamin A-rich vegetables skyrocketed and revived a struggling industry. In 2006, the average carrot consumption per American was 11.8 pounds, up from 9.63 pounds in 1980, according to the U.S. Department of Agriculture’s Economic Research Service.

Packaged salads

Consumers are increasingly grabbing bags or plastic clamshells of leafy greens at the grocery store. Packaged salads accounted for $3.7 billion in sales last year, an 8 percent increase from the previous year, according to Nielsen Perishables Group. An innovative type of plastic packaging protects the leafy greens from the air that causes them to brown or spoil. Essentially, the packaging “breathes” and changes the ratio of gasses to prevent spoilage, Snyder said. The shelf life can be double or even triple that of conventional greens. This type of packaging has resulted in more consumers choosing vitamin-rich leafy greens such as spinach, arugula, chard and kale. Americans’ consumption of leafy green and Romaine lettuce has increased from 3 pounds per person per year to more than 11 pounds, according to the USDA.

Pre-sliced, bagged apples

Sliced apples—they’ve been billed as the best thing since sliced bread. Their popularity skyrocketed after McDonald’s started offering bags of sliced apples in kids’ meals in 2004 as a healthy alternative to fries. Kids liked their white flesh, crisp taste and small size while parents liked this healthier option. Scientist Attila Pavlath and his team of researchers are credited with developing an edible, odorless and tasteless coating in 2000 that prevents apples from browning after they are cut. In 2014, Americans ate more than 500 million sliced apples—triple the amount consumed in 2004.

Sliced apples—they’ve been billed as the best thing since sliced bread. Their popularity skyrocketed after McDonald’s started offering bags of sliced apples in kids’ meals in 2004 as a healthy alternative to fries. Kids liked their white flesh, crisp taste and small size while parents liked this healthier option. Scientist Attila Pavlath and his team of researchers are credited with developing an edible, odorless and tasteless coating in 2000 that prevents apples from browning after they are cut. In 2014, Americans ate more than 500 million sliced apples—triple the amount consumed in 2004.

Members have three ways to apply: contacting a certified agent, calling 833-468-4280 or visiting ohiofarmbureauhealthplans.org.

Read More

Collegiate Farm Bureau serves as a connection to current industry professionals and equips the next generation with the essential tools and resources needed to excel in their careers.

Read More

Ohio Farm Bureau members met one-on-one with state legislators and staff to discuss policy priorities impacting Ohio’s farms and rural communities.

Read More

Legacy nutrient deductions enable new farmland owners to claim deductions on the nutrients within the soil on which healthy crops depend.

Read More

Farmers, agribusinesses and community members are encouraged to nominate their local fire departments for Nationwide’s Nominate Your Fire Department Contest through April 30.

Read More

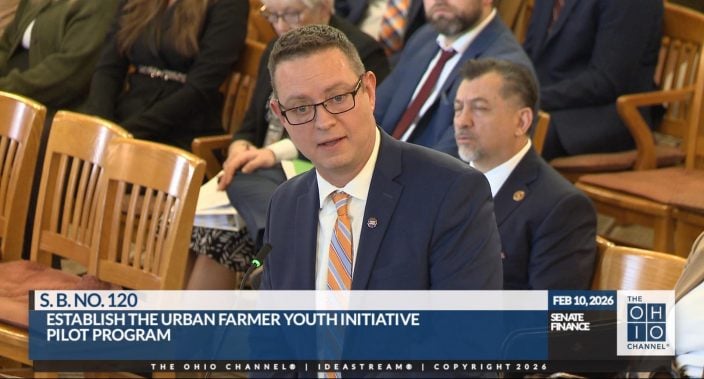

Introduced by Sen. Paula Hicks-Hudson, SB 120 would establish the Urban Farmer Youth Initiative Pilot Program.

Read More

Gases, vapors, and fumes can all create risk. How can we measure and protect ourselves from them?

Read More

The Ohio Farm Bureau’s Young Agricultural Professionals State Committee has named its 2026 leadership and the individuals who will be serving on the state committee for 2026-2028.

Read More

The Ohio Farm Bureau Foundation has multiple scholarships available to Ohio students from rural, suburban and urban communities who are pursuing degrees with a connection to the agricultural industry.

Read More

With 100% bonus depreciation now permanent, farmers can deduct the full cost of a new agricultural building in the year it’s placed in service.

Read More