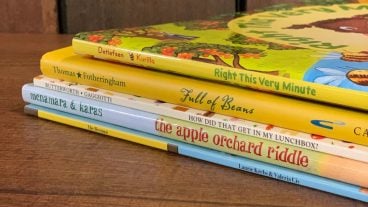

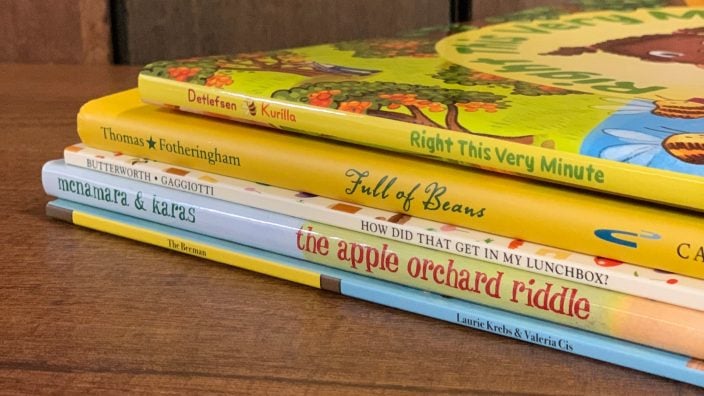

Real books about ag for kids fuels Feeding Minds Press

The latest Feeding Minds author is Ohio Farm Bureau member Michelle Houts of Celina.

Read MorePoultry have ruled the roost at this New Carlisle farm since 1948, when Kenneth Bowman and Dennis Landes went into the turkey business together. At the time, they were one of several turkey farms in the county. Now, they are the only ones.

A relatively quiet flock of turkey hens, a few hundred strong, waddles out of the tall corn stalks and over to well-worn feeding troughs in their free range oasis, a pocket of land surrounded by a burgeoning suburbia in Miami County.

Poultry have ruled the roost at this New Carlisle farm since 1948, when Kenneth Bowman and Dennis Landes went into the turkey business together. At the time, they were one of several turkey farms in the county. Now, they are the only ones.

“We have about 70,000 turkeys,” said Steve Landes, company president. “But to the industry, we don’t exist.”

Yet, they have grown, steadily, through four generations for almost 75 years.

Just to the east of where the recently expanded Bowman & Landes deli and market operates sits the house Dennis Landes, 99, just moved out of in 2019. His former home became office space and a conference room, with homey features still very much intact.

Just to the east of where the recently expanded Bowman & Landes deli and market operates sits the house Dennis Landes, 99, just moved out of in 2019. His former home became office space and a conference room, with homey features still very much intact.

Attached and behind the market is a large, also recently expanded processing and storage facility. From one-day poults to processing, the company sees their product through from start to finish.

Steve Landes, his brother Stan, and Carl Bowman are all sons of the original owners. Stan and Carl are semi-retired. They remember some of the more unique aspects of the early days on the farm, like turkeys being dropped down from one level to another in a chute for processing years ago, something that would not happen today.

“It’s hard work and the market has changed,” Carl said. “There used to be corner meat market shops and small processing plants, and that has changed, too.”

While Bowman & Landes does count on regional retailers to stock their products in local stores, they sell a lot of it out of their market at the farm.

They also do all their own processing, which is important in a challenging time for agricultural supply chains (see sidebar). For 20-plus days in November, it’s all-hands-on-deck to get the centerpiece of the Thanksgiving feast ready for loyal customers, many who come back year after year, generation after generation.

Two years ago, the cramped former processing and packaging facility was reimagined. The result is a 26,000-square-foot, state-of-the-art facility that is not only larger, but also meets standards set by USDA inspections, which take place on the farm daily. The space allows for both raw and cooked meat to be packaged separately. It also includes a new cooler and freezer.

Expanded space is only one aspect of Bowman & Landes’ steady growth and innovative practices they have employed since the beginning, including those free range birds.

“In the late 90s, early 2000s we realized that we’d always done it (free range), so why don’t we say so,” Steve said.

Carl said they asked themselves, “what can we do that others aren’t doing?” Supplying a product grown with non-GMO grain was the answer, so they decided to implement that, too.

In another nod to innovation and protecting the environment, the business installed the first of its solar arrays on the south side of the turkey barns in 2011. They now have three sets of solar arrays, the last one being installed in 2020 and powering more than the other two combined because of advances in the technology. All told, the solar energy powers half of the operation, including the new processing and packaging building.

When not in the barn, the turkeys live on 10 separate open pastures, complete with shade shelters, depending on age and feed. Flocks are separated by feed type, which includes grain from the 2,800 acres the company farms in the area.

With retirement on the horizon, and community development inching closer to the turkey barns, many farmers might be more than a little concerned about what the future holds.

That’s not the case with these farmers.

“If you’re not growing you’re dying,” Carl said. “We’ve always grown slowly. We never went for home runs. We’re steady at it and it’s a good formula for us. I’m super excited about the next generation and the talent we have.”

Jon Hamber, son of Carl’s sister, Anita Bowman Hamber, has spent a lot of time recently making enhancements to the processing facility. Seemingly simple things, such as weighing and labeling each box of processed turkey through automation, are new to Bowman & Landes. Such enhancements save on manpower and time, and as a third generation co-owner in the company, it is important to him.

However, Jon’s background is in automation mechanics. He came back to the farm four years ago after earning a degree in industrial design from Columbus College of Art and Design and working in the private sector for eight years as a machine designer.

“I was sitting behind a desk 10 hours a day,” he said. “I like being physically active. I don’t want to sit still 10 hours a day. I don’t sit still on the farm.”

In addition to his meat plant plan responsibilities, Jon is also designing Bowman & Landes billboards and marketing materials, putting his degree to use.

He isn’t the only one who decided coming back to the family farm was the right move for him.

On a sunny mid-September afternoon, Eric Landes, another third generation employee, was driving a truck headed to Cargill after an early corn harvest. The combine harvesting the corn was operated by the first of the fourth generation working full time in the company, Myles Landes, son of farm manager Dan Landes.

Eric’s job description includes meat plant responsibilities, maintenance and IT, but is augmented by a degree in computer engineering.

“He’s working on our e-commerce platform, too,” said Drew Bowman, noting that Bowman & Landes has an eye toward more online ordering and shipping in the future.

Drew himself is also a third generation co-owner, coming back to the farm after years working in finance in New York. He’s the “black sheep of the family” he said, because he still lives in Columbus, where his wife is employed, and drives in to work daily. His job responsibilities include retail and wholesale sales and marketing.

When he earned his degree in finance from Miami University, Drew said “the last thing I wanted to do was work at the turkey farm.” A conversation with his dad seven years later changed his mind.

“I didn’t feel like I was making a difference,” Drew said of his former career. “I felt like I was working ‘for the man,’ but in this small business I can make a difference. I’m very grateful to have the opportunity to come back.”

Changes in the farm over the years also prompted Anita, who lived in England for more than 20 years, to want to come back with her family (including 10-year-old Jon) in 1997. She is in charge of retail sales and marketing. When she visited, she would see the small modernizations taking place and decided there was a place for her and her family.

“Never did I ever think I would be back here,” she said. “But they were doing an excellent job and I saw it unfolding.”

Strictly talking turkey, Drew knows the way Bowman & Landes raise their product isn’t for everyone.

“We’re not the biggest, and we don’t think anyone is doing it wrong, but this way works for us,” Drew said. The birds live a free range, low stress life before they are harvested, and he said the difference is in the taste of the meat.

Beyond those 350,000 kilowatt solar arrays, the company does everything it can to preserve the land and maintain soil structure. They use no-till and minimum till practices, utilize cover crops and maintain waterways. Bowman & Landes uses turkey manure to fertilize fields, recycles cardboard and plastic and uses modern energy efficient LED lighting throughout.

”There is a lot of sweat equity here,” Steve said. “Every year we look at how to make the operation better and make it easier on people to do their jobs.”

All agreed that the families have always worked well together and brought different strengths to the table. Steve even quotes Ecclesiastes to drive the point home:

“Two are better than one, because they have a good return for their labor: if either of them falls down, one can help the other up.”

The latest Feeding Minds author is Ohio Farm Bureau member Michelle Houts of Celina.

Read More

80 Acres Farms’ newest farm blends the science and wisdom of farming with the efficiency and precision of manufacturing that allows the farm to deliver on its mission of growing high quality produce all year long.

Read More

It takes time to both build community support and then to build out the fiber network itself, but Ohio Gig doesn’t go into a community looking for a monetary investment, but a credibility one.

Read More

Great Lakes is unique among ag labor consultants because it’s grassroots, conceptualized and developed by and for farmers who are members of Farm Bureau.

Read More

The YAP State Committee member saidhHer introduction to Farm Bureau came via the Young Agricultural Professionals winter leadership conference while she was in college.

Read More

Ohio Farm Bureau Foundation can accept ‘grain gifts’ from farmers who want to support the future of agriculture.

Read More

Poultry have ruled the roost at this New Carlisle farm since 1948, when Kenneth Bowman and Dennis Landes went into the turkey business together. At the time, they were one of several turkey farms in the county. Now, they are the only ones.

Read More

At the 103rd annual meeting, in addition to updating our organization’s policies through our grassroots framework, this year’s meeting also will require our delegate body to consider revisions to our code.

Read More

When Ohio landowners are faced with losing property rights through eminent domain, the law doesn’t make it easy for them to defend their own interests.

Read More